Our Blog

View our latest news and upcoming events.

Pigments vs Dyes: Understanding the Differences Between Dyes and Pigments

Pigments vs Dyes: Understanding the Differences Between Dyes and Pigments Pigments and dyes represent the two principal types of colorants. A basic level of understanding of the differences between these classes of colorants will provide a helpful foundation of...

Pylam Dyes now offering resin chips

From the Lab…… As our customers know, we spend a great deal of time and resources communicating about the available dye and colorant options for both their projects and their problems. For many of these requests, solvent dyes are the best colorant option. However,...

The COVID-19 virus has left the world in unprecedented and uncertain times PPCI

The COVID-19 virus has left the world in unprecedented and uncertain times. As different countries and states implement their own responses to the virus and the world continues to change, it is critical that we take action where we can. One of the main ways everyone...

Acid Blue 145 Shortages

Are you having a hard time finding Acid Blue 145 (CAS 6408-80-6)? You are not alone. The worldwide dye and colorant market has been heavily impacted by supply shortages stemming from stricter environmental and regulatory controls implemented by both the Chinese and...

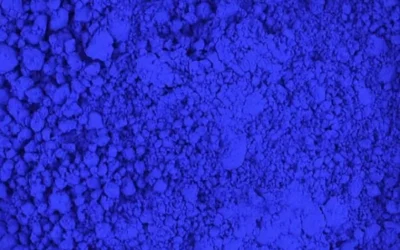

Ultramarine Blue

What is Ultramarine Blue? Ultramarine Blue is one of the most sought-after pigments. Historically, Ultramarine Blue (a.k.a. Lapis lazuli) was mined from the earth, and it was prized for its deep blue hues when used in paints. However, the colorant was prohibitively...

Vinegar and Easter Egg Dyes

We know that many people may wonder about the best way to color Easter eggs this time of year. We feel that the detail below is a good example of how dyes can be employed. Most Easter egg dying kits instruct the user to mix a small amount of white vinegar along with...

What is the difference between organic and inorganic pigments?

Inorganic versus Organic Pigments In a previous post—Dyes versus Pigments—a comparison between dyes and pigments was provided along with clarification that, regardless of their differences, both dyes and pigments fall in the “colorant” family of chemical compounds....

New Product Announcement Pylakrome Red VS LX-12137

Pylam maintains an inventory of thousands of distinct dyes, pigments, and blends of colorants. Our PYLAKROME RED VS LX-12137 is a high-tinctorial strength dye with outstanding solubility, good heat stability, and good lightfastness. Please consider receiving a free...

Pylam Fiber Identification Stain #4

Pylam Products has been offering Pylam Fiber ID Stain #4 since the 1970s. For nearly forty years we have been supplying one of the greatest fiber identification systems to the pharmaceutical, textile, and manufacturing industries. Whether you need to comply with USP...

Difference Between Dyes and Pigments

What is the difference between dyes and pigments? Dyes versus Pigments Both dyes and pigments fall under the umbrella term of “colorants.” Dyes and pigments are both used to color materials, although the way in which the coloring process takes place is different for...

Need a Sample

Request a sample below